There’s value in planning.

The heart of our scheduling program, introduced during the pre-construction phase is the Lean work schedule. This approach enhances the way work is performed throughout the construction delivery process by reducing inefficiencies, which will eliminate miscommunication and increase project efficiency, ultimately saving money.

Lean Construction Strategies

Our team at Meyer Najem is dedicated to continuous improvement. One way to achieve this is through our Lean practices in the pre-construction and construction phases. Lean Construction is not only a tool, but a philosophy and a culture. Lean practices will maximize the value of your project and eliminate unwanted waste to provide cost savings.

All decisions and processes are value generated for our clients, as well as Meyer Najem. If it does not add value to the project, then it is waste and should be removed from the project. We focus on the process and flow, allowing us to manage minor or major improvements to improve the entire project. Our mindset is always on continuous improvement because there is always a better way to complete a task.

At Meyer Najem, we encourage open dialogue and innovative ideas from internal and external resources. A key to continually developing better practices is to remove the waste. We think of the entire project; Optimizing every factor keeps our focus not only on the trivial things, but on the entire project.

We have implemented the following practices within our company and with our trade contractors to promote our Lean principles:

Prefabrication allows various building elements, from bathrooms and plumbing, to pre-wired light fixtures and exterior walls, to be built in an off-site environment and transported to the job site, increasing quality and used a cost-savings measure in the process.

Modularization creates repetition, which in turn creates better quality and decreased fabrication time, allowing contractors to improve their process and save money. The focus is on making the process better, rather than learning how to complete a different task each time.

A Virtual mock-up gives the owner a visual of the product before it is built, which allows changes to be made with little to no schedule changes and a low-cost impact on the project.

Physical mock-ups give the owner a chance to feel the space. An Example of this is creating a fully mocked-up room before it’s completed. This gives the client a sense of what the final product will be like, ensuring that it is what they want and works for their needs.

Just in Time Delivery is the idea that items should not be delivered until they are needed. If it is in the way, then we are wasting resources such as storage, deliveries or object relocation, which can lead to added expenses.

Module based estimates are estimates linked to a Building Information Model (BIM), which provide quantities and unit costs to specific components of the project, allowing our team to be precise with our bids and have little to no scope overlaps, or extra expenses.

We believe in working as a unified team in collaboration. Team sessions and meetings are important for our company culture. As a team, we resolve any issues or crucial decisions that need to be made. Regardless of contract structure, we ask for architects, engineers, consultants and subcontractors to provide their input on subjects.

We believe in “better practices” in lieu of “best practices”. Best practices would imply that there is not a better way to do something and hinders continuous improvement. We are always striving to find a better way to do things, with input from the entire team.

We have utilized standardization in our processes and procedures so that everyone understands the baseline of our company’s practices. This gives us a starting point for improvement. We then revisit our processes and procedures to improve upon them.

This process is key to constant improvement. While a task is in progress, we collect data and information and look at what it took to complete the task. Once information has been collected, we analyze the data to recognize trends. After we have the analysis, we can then make improvements to the task execution. It is important to repeat these steps to improve our process to create value for the company and owner, by increasing our efficiency and productivity.

Lean Construction Institute Experience

Meyer Najem and the Lean Construction Institute (LCI), recognize seven types of wastes, which we are staffed to identify and eliminate from our processes. By eliminating waste, we can handle our projects in a more efficient and economic manner, providing a quicker execution time. Our process also saves resources for other tasks, which provides much added value for our clients.

The seven types of wastes that we look for include:

Motion – A non-value-added activity

Waiting – Periods of inactivity

Over Processing – Unnecessary steps taken

Over Production – Making more, faster or earlier than needed.

Defects/Quality – Reworking or remaking products

Transport – An unnecessary movement of materials

Too Much or Too Little Inventory – Resources or space tied up

Last Planner System

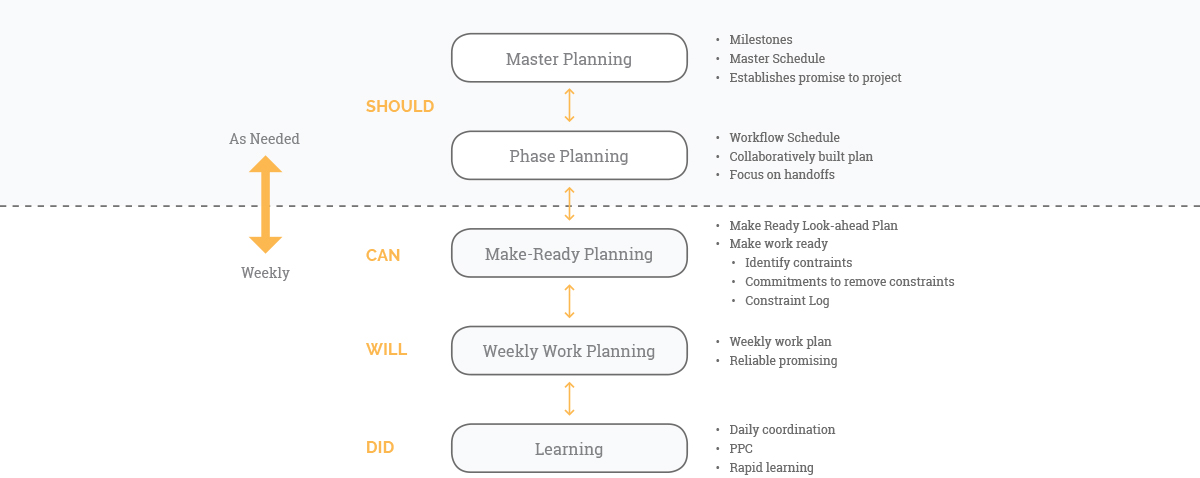

Our team utilizes Lean Principles and the Last Planner System (LPS) for our scheduling process. Below is a basic flow chart of how LPS works.

Master Planning takes place during preconstruction, while Phased Planning is focused on through the duration of Make-Ready Planning, Weekly Work Learning and Learning.

Phase Planning, sometimes known as Pull Planning, is a scheduling coordination process, where we select a portion of the schedule between two major milestones. Once we have identified the magnitude of the Pull Plan, we then schedule a meeting with all the trade contractors involved in the phase of the project.

Our team then conducts a Pull Plan meeting, working on our schedule in reverse order, starting with project completion and working backwards. The tasks associated with each milestone are reviewed with the appropriate contractors who commit to the work schedule that will be completed and the manpower required and what activity needs to be completed before their activity. This process gets the trade contractors to buy into the project schedule, promoting peer accountability. Once completed, we address material lead times, identify coordination items and account for any scheduling conflicts, all of which add value for our clients.

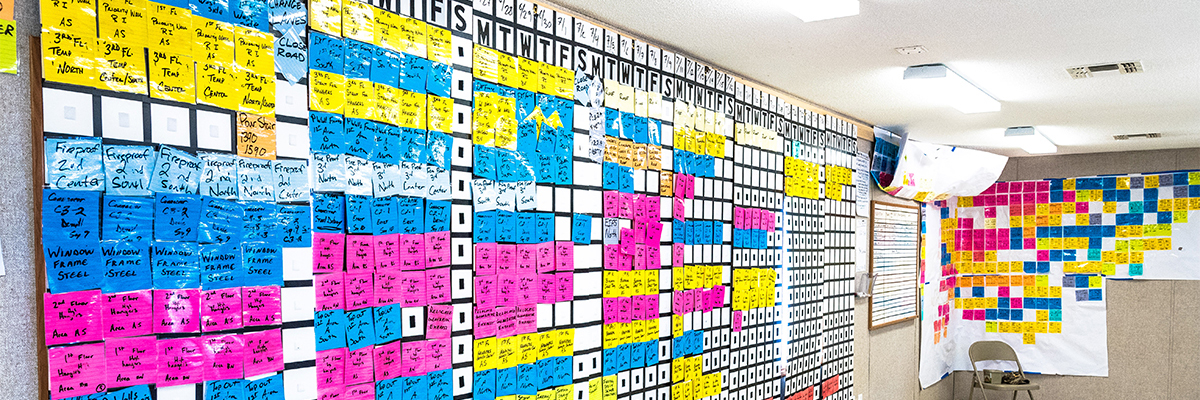

Once Pull Planning has been conducted, the schedule is posted in our jobsite trailer on Weekly Planner Boards. This step in the process incorporates both Make-Ready Planning and Weekly Work Planning. The planner boards are six weeks of the project schedule. The first board is the previous week’s tasks, the second board is the current week’s tasks and the next four boards are the four weeks look ahead boards. These boards are a revolving schedule that the Last Planner, or foreman and superintendent, use to manage their activities and actualize the schedule.

The last step of the Last Planner System is Learning. In Lean, the major principle is constant improvement. To keep improving we must collect and analyze data. This allows us to find better ways of completing tasks, identify trends and point out areas of improvement.

Integrated Facility Design Experience

Integrated Facility Design (IFD), is tested to eliminate alternatives. The process allows for the design team to test multiple scenarios, reducing lead time in the design process. We have outlined our steps in conducting and participating in a typical IFD process with Lean principles in mind.

Establish the Project Team or Leadership Committee. Far too often silos form, representing different divisions of the pre-construction and construction teams to establish this, we establish the leaders or key stakeholders and bring them together for design sessions and regular progress meetings. During this step, the key stakeholders work in conjunction with the IFD consultant to outline specific roles and tasks for the project.

Outline the client’s project goals. In this step, we set up and participate in a Collaborative Design Session (CDS) that allows us to identify the client’s conditions of satisfaction. These are specific operational goals that the client is looking for the project team to meet. Examples of this would be increasing energy efficiency, reducing maintenance cost, reducing travel distance or creating an environment that is state-of-the-art. We then evaluate these goals and ensure that the team has a clear definition of the clients goals.

Identify the facility goals and/or requirements. This step requires another Collaborative Design Session to identify the specific requirements of the building. If the budget is $50 million, why? What does the client expect for this amount of money? Do we need 50,000 or 100,000-square feet? What is determining the amount of square footage needed? Can we do more with the budget?

These are the types of questions we ask the client to define before utilization of the facility can begin. From this point, we can utilize the Target Value Design (TVD) method. This is a method that promotes design, provides critical values and develops a design within a project’s limitation, outlined by the client.

Choosing by Advantages (CBA) provides the team with a visual and transparent decision-making process, aligning with the core values and principles of Lean Construction. CBA leads the team to emphasize a project’s value to its client. The CBA method allows the project team to reach consensus and focus on the final product.

Value Streaming (Operational Strategical Analysis) is a process that outlines the process flow and provides a functionality check. It helps make problems visible, breaks down functional silos, creates leadership alignment, builds external focus and defines the project performance metrics. In this step, we review conceptual design with the goals and requirements outlined in the previous steps.

Design Cycle Detailing is providing the clients with mock-ups at every stage of the design and construction process so that the project team can provide the best product. We utilize virtual mock-ups, virtual walk-throughs, prop mock-ups and early in-place mock-ups. Each version of these mock-ups, serve a purpose of showing the client the current design and its functionality.

Practicing IFD has been proven to increase three major factors in a project’s success:

The first major benefit is that the project goals are met. This is a goal that our team strives to meet on every project.

The second benefit is that the construction team has a much higher success rate through completed drawings that provide a better understanding of the purpose and goals of the design.

The third major benefit is overall client satisfaction. Too often there is a disconnect between the project team and the end-user’s needs. The IFD process is the answer to this issue.